Plastics have turned into an irreplaceable piece of our cutting-edge world, finding applications in different enterprises, going from auto to medical care. With the growing concern over ecological supportability and the requirement for effective Rotomolding processes, the future of plastics lies in creative advancements like rotomolding.

Prologue to Rotomolding Technology

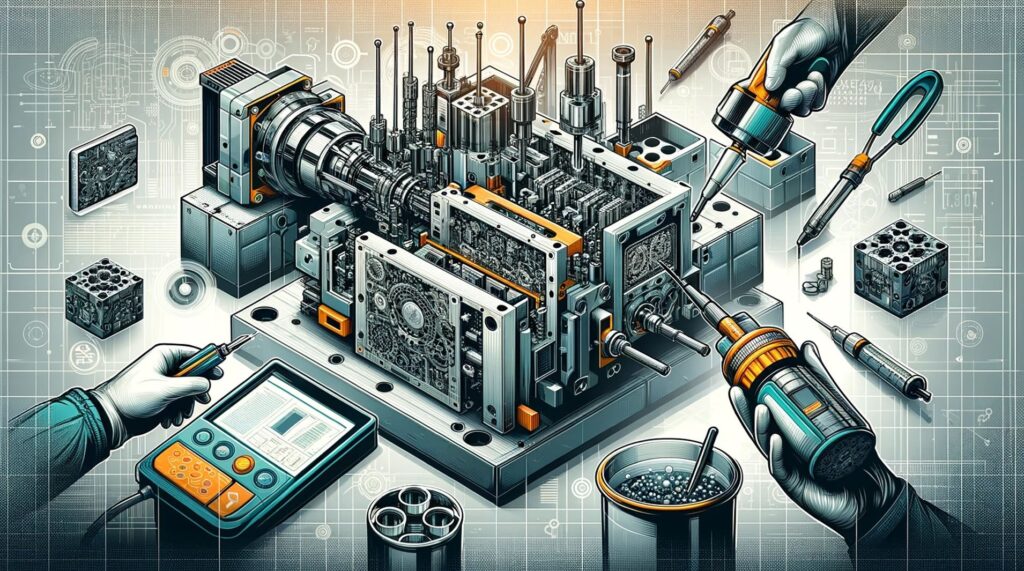

Rotational embellishment, ordinarily known as rotomolding, is an assembly cycle utilized for delivering empty plastic items. Dissimilar to conventional trim methods that include high strain and complex tooling, rotomolding offers a less complex and more financially savvy arrangement.

Understanding the Rotomolding System

- Warming and Dissolving Plastic: The interaction starts with adding a deliberate measure of powdered tar to an empty form. The shape is then warmed in a broiler, making the plastic liquefy and stick to the form’s inward surface.

- Pivoting the Shape: When the plastic has dissolved totally, the shape is turned gradually along different tomahawks. This rotational development guarantees uniform appropriation of the liquid plastic, bringing about steady wall thickness and unrivaled-quality items.

- Cooling and Setting: After pivot, the form is cooled either via air or water shower, making the plastic set and take the ideal shape. When cooled, the completed item is taken out of its shape and prepared for further completing cycles.

Advantages of Rotomolding Technology

Rotomolding offers a few advantages over customary embellishment techniques:

- Plan Adaptability: One of the critical advantages of rotomolding is its unrivaled plan adaptability. Complex shapes, undermines, and perplexing subtleties can be effectively accomplished without the requirement for costly tooling.

- Cost-Viability: Because of its low tooling costs and negligible material waste, rotomolding is an exceptionally savvy fabricating process, particularly for small to medium-sized creation runs.

- Toughness and Strength: Items made through rotomolding show remarkable solidity and strength, making them ideal for requesting applications in businesses, for example, cars and aviation.

Uniform Wall Thickness

In contrast to other embellishment methods, Rotational Molding guarantees uniform wall thickness all through the item, disposing of points of concern and upgrading underlying honesty.

While rotomolding offers various advantages, it additionally faces difficulties, for example, longer process durations and restricted material choices for specific applications. Be that as it may, continuous innovative work endeavors are tending to these difficulties, preparing for further developments in the field. As enterprises keep on looking for reasonable and productive assembly arrangements, the future of plastics lies in advancements like rotomolding. With its flexibility, cost-viability, and natural advantages, rotomolding is ready to assume a critical role in forming the future of plastic assembling.